Lee Friedlander - the New Cars 1964

Lee Friedlander - the New Cars 1964 by Lee FriedlanderIn 1964, two young art directors at "Harper's Bazaar" named Ruth Ansel and Bea Feitler hired the then up-and-coming photographer Lee Friedlander to photograph the much-anticipated new car models of that year. Friedlander's jazz album covers had proven he knew how to work on assignment, and Ansel and Feitler realized that if "Bazaar"was to obtain the photographer's best work he should be let alone to make it. It's difficult now to comprehend how anticipated next year's cars were to Americans of the 1960s, but if Friedlander was aware of this, the photographs he delivered (on time) don't betray it. Rather than depicting the cars in seductive locales, he had them delivered to parking lots near burger joints, cheap furniture stores, downscale beauty parlors and--most ignominiously of all--a used-car lot. As Friedlander says, "I just put the cars out in the world, instead of on a pedestal." The magazine's editor-in-chief was unamused, fearing that the photographs would deter car manufacturers from advertising in "Harper's," so Friedlander was paid for his work and the photographs were soon forgotten--until he stumbled across them in 2010. Even a cursory study of this project reveals a compendium of strategies that would soon bring Friedlander acclaim and wreak havoc with widely accepted notions of what constituted a good photograph. Now, the Continentals, Eldorados and Mercury Meteors of 1964 have their day in this beautifully produced volume. Lee Friedlander - the New Cars 1964 by Lee Friedlander |

Our team have been selling workshop and service manuals to Australia for the past 7 years. This online store is committed to to the trading of workshop manuals to only Australia. We routinely keep our manuals in stock, so right as you order them we can get them shipped to you promptly. Our freight shipping to your Australian destination ordinarily takes one to 2 days.

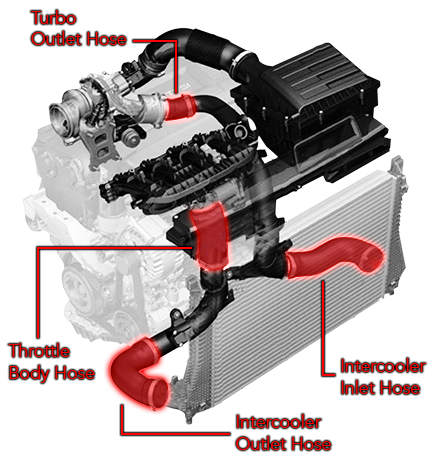

Maintenance and repair manuals are a series of useful manuals that primarily focuses upon the routine service maintenance and repair of motor vehicles, covering a wide range of models. Workshop manuals are geared mainly at repair it on your own enthusiasts, rather than professional workshop mechanics.The manuals cover areas such as: ignition system,injector pump,pcv valve,replace tyres,alternator replacement,ball joint,alternator belt,oil pump,batteries,brake pads,bell housing,signal relays,change fluids,coolant temperature sensor,gasket,distributor,wiring harness,replace bulbs,valve grind,sump plug,ABS sensors,spark plugs,throttle position sensor,fuel gauge sensor,adjust tappets,clutch pressure plate,gearbox oil,overhead cam timing,clutch cable,stub axle,glow plugs,CV joints, oil pan,starter motor,spark plug leads,oil seal,stripped screws,crank pulley,radiator hoses,radiator flush,fuel filters,exhaust pipes,drive belts,brake rotors,headlight bulbs,tie rod,brake piston,suspension repairs,oxygen sensor,thermostats,head gasket,bleed brakes,brake drum,master cylinder,turbocharger,grease joints,camshaft timing,conrod,exhaust manifold,diesel engine,engine block,warning light,wheel bearing replacement,engine control unit,brake servo,trailing arm,supercharger,exhaust gasket,blown fuses,anti freeze,petrol engine,pitman arm,rocker cover,seat belts,radiator fan,window winder,cylinder head,window replacement,slave cylinder,caliper,camshaft sensor,knock sensor,steering arm,fix tyres,Carburetor,clutch plate,o-ring,brake shoe,CV boots,shock absorbers,crankshaft position sensor,spring,piston ring,crank case,stabiliser link,water pump

0 Items (Empty)

0 Items (Empty)